Shahzad Ashraf1* , Tauqeer Ahmed1

, Tauqeer Ahmed1 , Sehrish Saleem2

, Sehrish Saleem2 and Zeeshan Aslam3

and Zeeshan Aslam3

1College of Internet of Things Engineering, Hohai University Changzhou Jiangsu China

2Muhammad Nawaz Sharif University of Engineering and Technology Multan Pakistan

3Petroweld Oilfield Services Kurdistan, Iraq

Corresponding Author Email: nfc.iet@hotmail.com

DOI : http://dx.doi.org/10.13005/ojcst13.01.02

Article Publishing History

Article Received on : 13 April 2020

Article Accepted on : 23 May 2020

Article Published : 25 May 2020

Plagiarism Check: Yes

Reviewed by: Anurag Dasgupta

Second Review by: Pritheega A/P Magalingam

Final Approval by: Dr. Muhammad Hafidz Fazli Bin Md Fauadi

Article Metrics

ABSTRACT:

The sustainability and environmental considerations have slowly become divergences, but having greatest influence in the supply chain management that must be contemplates to examine the environmental and organizational factors. The research considers environmental and sustainable strategies within companies, the efficient supply chain management strategies for manufacturers and consumers, and to the environment friendly product design and services, taking a case-by-case perspective and concentrating on enterprise businesses scale. Our finding reveals that green supply chain management firms are delivering exuberant environmental efficiency at an added cost. Among the identified obstacles we identified different obstacles and conceptual relations and barriers are graded based on dependency and driving sand. In future, green policies have greater customer services avenues thereby, appeal for suppliers, manufacturers and officials.

KEYWORDS:

Supply Chain; Diverging Trends; Green Management; Bodacious Management

Copy the following to cite this article:

Ashraf S, Ahmed T, Saleem S, Aslam Z. Diverging Mysterious in Green Supply Chain Management. Orient. J. Comp. Sci. and Technol; 13(1).

|

Copy the following to cite this URL:

Ashraf S, Ahmed T, Saleem S, Aslam Z. Diverging Mysterious in Green Supply Chain Management. Orient. J. Comp. Sci. and Technol; 13(1). Available from: https://bit.ly/2zqn2vV

|

Introduction

In the past few years, Green Supply Chain Management (GSCM) has

gained increased coverage.1 GSCM’s criteria have expanded because of

public interest, cultural, environmental or legislative causes. The GSCM

includes traditional management of the supply chain that integrates

environmental criteria and concerns in the decision on purchasing organizations

and long-term relationships with suppliers. It is about confining waste, within

the industrial system to conserve energy and prevent hazardous materials from

being dissipated to the environment. The GSCM principles are commonly

understood by industry as tracking the environmental performance of suppliers.

However, conscious trade activities have been gaining growing consideration. In

their policy designs an increasing number of businesses are pondering on the

amalgamation of ecological practices.2 Costs are one of the greatest

barriers to the green supply chain. The time and resources needed to transform

a company’s existing processes into greener are not sufficient to justify

changes by the top management. The environmental impact will occur at all

stages of the supply chain and the lifespan of a product, and GSCM emerges as a

major new strategy for businesses to achieve a reduction in their ecological

impact.3

Manufacturing executives are in charge of the operations of the

organizations under which they are involved. How can they best improve the

performance of organizations in their supply chains? Local managers must first

and secondly adopt decisions supporting the supply chain. In the light of the

environmentally friendly goods or services created by environmentally

sustainable practices and government environmental legislation, manufacturing

companies have started adopting green supply chain management (GSCM)

activities. Such activities allow producers to collaborate with vendors and

consumers to increase the quality of the environment.4 In order to

increase the environmental efficiency of GSCM operation, reductions in air

pollution, effluent waste, solid waste and the use of hazardous materials are

required. However, there is fear that this focus on environmental protection

would eventually lead to stronger market share and productivity.5

GSCM V/S Regular SCM

Table 1: Characteristics of GSCM and SCM

| Sr.No |

Features |

Green Supply Chain Management |

Conventional Supply Chain Management |

| 1 |

Objectives |

Ecological and Economic |

Economic |

| 2 |

Ecological Optimization |

High Ecological Impacts |

Integrated Approach Low ecological impacts |

| 3 |

Supplier Selection criteria |

Eco logical Aspects Long Term relationship |

Short term partnerships Cost change vendors rapidly |

| 4 |

Cost Pressure |

High |

Low |

| 5 |

Flexibility |

Low |

High |

| 6 |

Speed |

low |

High |

The GSCM and the Conventional SCM,6 are distinct in different ways. GSCM takes environmental and economic issues as a goal, whereas Traditional SCM is typically based on the economy as a single objective. GSCM are renewable, interconnected and ecologically efficient, whereas conventional SCM does not take into account human toxicological consequences. Conventional SCM relies mainly on managing the finished product; no matter how detrimental the consequences are to the ecosystem during manufacturing and delivery.7 Ecological standards are crucial conditions for goods and exports and, at the same time, the company must maintain its economic survival by being competitive and sustainable. The discrepancy between GSCM and SCM is summarized in Table 1.

Mystery to Implement Green Supply Chain Management

There are numerous driving barriers which hiatus to a smooth

implementation of GSCM specially related to automobile industry. As the automobile

industry is world’s largest single manufacturing sector. The rise in the

population of the world has also boosted demand for automobiles. Enterprises

must concentrate on energies and capital to keep the supply chain

environmentally friendly.8 The biggest hurdles in the automobile

industry are the introduction of GSCM are

- Lack of IT Implementation

- Resistance to Technology Advancement Adoption

- Lack of Organization Encouragement

- Poor Quality of Human Resources

- Market Competition and Uncertainty

- Lack of Government Support System

- Lack of Implementing Green Practices

- Lack of Top Management Commitment

- Cost Implications

Methodology

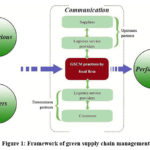

A conceptual framework of GSCM has been illustrated through Fig.

1, that encompasses the drivers, mysterious, and the performance. Drivers are

the stimulator that motivates or even forces focal

companies to follow the GSCP. A stronger presence of the drivers results in a

quicker adoption of GSCP because the inability to respond to the driving force

timely might result in a threat to the existence of the firms. In contrast,

there are barriers that exist which hinder the implementation process of GSCM.

It can be concluded that the stronger the presence of these barriers, the

poorer the implementation level of GSCM. Green arrows represent the positive

relationship between drivers and the entities.9 A stronger

involvement of the drivers results in a faster adoption

of GSCP as the failure to respond to the driving force

timely could result in a challenge to the life of the

firms. In comparison, there are obstacles that exist which hinder

the deployment phase of GSCM.

Related Findings

It’s a common saying that compliance with the legislation is a

primary component of green buying. It is predicted that the impact of

environmental regulations on purchasing activities will become the second

biggest issue in the future.10 Although the relation between Green

Supply Chain Management (GSCM) and the success of the companies was examined,

the results were not conclusive. There are two opposite theories concerning the

relation between performance and the effect on the environment. The first

argues that environmental management should only ensure compliance with the

legislation and the second suggests that environmental management should be

able to raise costs and expenditures in order to produce better performance.11

The effect of environmental parameters on investment in the use of

electricity concluded that they related to the decline in industrial

production. An optimistic link between the performance of a firm and

environmentally friendly practices was reported in. The suggested structure and

empirical findings indicate a positive effect on market share and cost from

ecological practices. Recent work has provided an overview of the future nature

of supply chain activities to enhance efficiency in an environmentally sustainable

way. Smaller and more regional businesses have been found easier to adopt more

environmentally sustainable approaches.12 Connecting with owners promotes

the adoption and development of innovative environmental technologies, while

working with customers and staff and cooperative R&D leads to better

results in climate. The real long-term economic effect is not easily measured

by considering a single factor, such as productivity in the short run or sales

performance. Companies’ impact on the environment face increased cost of

production, but are also projected to slowly gain an increased market share.13

Authors in,14 noted that environmental management is in

essence an innovative environmental design for institutional efficiency

enhancements. It has been reported that an eco-efficient approach to

administration is capable of improving the functional efficiency of a firm. A

clear connection has been identified between target meetings and the

contribution of staff to environmental administration. Cost returns will be

positively affected if consumers choose environmentally friendly business products

/ services, while expenditure can be reduced by diligent management of

environmental criteria that can trigger hurdles.15 Furthermore,

eco-friendly strategies can lead to developments that can provide businesses

with a head-start advantage, at least from a marketing point of view. A

positive relation between community, business performance and benefit has also

been documented. Nevertheless, empirical studies about GSCM practices should be

listed as scarce. The questions set out during finds are: i) what are

the effects of the green supply chain on firms’ environmental and functional

efficiency, and ii) what kinds of environmental management activities

are recommended to boost the company’s eco-efficient efficiency.

Table 2: Effective environmental Trends

| Environmental management trends |

Trends of GSCM for suppliers and consumers |

Environmentally oriented quality and service architecture |

System quality |

Operational quality |

| GSCM commitment from senior and middle-level executives |

Sustainable collaboration with manufacturers |

Environmentally safe raw ingredients |

Solid / liquid waste and emissions control |

Price savings and productivity boost |

| Maximum resource sustainability control |

ISO 14000 approval of the manufacturer |

Development of goods with decreased content and energy usage |

Reduction of hazardous / toxic material intake |

Improved product consistency |

| Green policy and inspection Program |

Company-wide assessments of the workplace |

Material construction for reuse, recycling and content recovery |

Minimization of environmental incident incidence |

Different prospects for the sector |

| Excepting trends |

Corporate regulation for local vendors |

Material construction to prevent or reduce the use and/or production of dangerous goods |

Electricity consumption loss |

Enhance the morale and efficiency of workers |

The study framework is designed to explore the connection between the various GSCM practices.16 In the literature, there is agreement that eco-friendly activities are a crucial factor in increasing the success of a firm. Previous research illustrated multiple GSCM measurements (Table 2).

The study framework is designed to explore the connection between the various GSCM practices.16 In the literature, there is agreement that eco-friendly activities are a crucial factor in increasing the success of a firm. Previous research illustrated multiple GSCM measurements (Table 2).

It was found that support from moderate-scale, executives, apart

from management guidance, is also a key factor in the successful implementation

of the GSCM. It has also been observed that GSCM can deliver many advantages

from cost savings to increased public participation (i.e. establishing a trend)

in the company’s strategy and, ultimately, increased market share. So

environmental issues are becoming a clear component in corporate tactical

patterns.17 Green ads and environmentally friendly packaging are

activities which could boost the supply chain’s environmental impact. To

highlight the environmental impact of packaging, some countries have programs

aimed at minimizing wrapping costs. It has been stated that standardized

recyclable containers and fine merchandising designs reduce availability and

turnaround time, rendering the product cost-effective while still being

environmentally friendly. Eco-efficient manufacturing of warnings and

procedures may combine many such concepts, from the use of materials and

resources during the first stages of the supply chain, to introducing

sustainable practices to reduce solid and liquid waste, to using

environmentally friendly logistics. Consequently, the Return on Investment

(ROI) was considered a key aspect of GSCM.

Finding Mysterious

Based on public data, the GSCM operations of four major

organizations are considered, depending on market shares, the position, data

quality and overall environmental policy, companies are chosen. Major firms have been chosen such that the principles and

practices mentioned can be used as a potential pattern guide for smaller firms

and policy makers.18

Eastman Chemical Company

Eastman focuses on sustainable supply chain management methods and

practical presentation improvement activities such as evaluating broker

contributions, designing supplier substitution approaches, designing broker

solutions, improving packaging, using recyclable packaging and promoting supply

chain networking, as well as developing consumer solutions and managing

material recovery. Eastman implements many environmental quantifiers and by

incorporating a greenhouse mitigation target, called TRI (Toxic Release

Inventory),19 has established the eco-efficient task practices. The

design of Eastman’s energy management strategy has balanced demand for fair

energy consumption with demand to minimize cost of production, for example by

ensuring that the heat generated is used in more than one chemical process. The

organization also claims to use effective water management methods and

recyclable materials to the wastage.20

Result and Discussion

This is sufficient to say that in the coming days, green emissions

are to be used as currencies. Measures to track the supply chain and quantify

future costs and obligations are also critical for multinational businesses. About 40% of companies have invested in renewable energy

production to combat energy inflation and rising domestic emissions, providing a

firm grip on energy costs and strengthening firm reputation and could even

become profitable when selling the surplus electricity generated. In order to

increase their market share, rising traders are battling the launch of

sustainable production. Sustainability is an opportunity for sales growth in a

significant number of participants. The areas where sustainability and carbon

policy opportunities emerge require reputation plus the brand name. Several

leading companies must assess in the sustainable chain management account the

full prospective and future advantages and profits. If the supply chain is

found to be communally insensitive, the credibility of a corporation is harmed.

Environmentally friendly and sustainable activities on the other hand boost a

company’s image and eventually, even with higher cost goods, its market shares.

An ethical supply chain is critical for a business. Enhanced risk

management and reputation are the practical component to be incorporated into

the current framework. Companies that use SSCM activities have major

environmental and functional impacts. Such work was constrained by the ease of sampling,

so that more detailed case studies could be performed.

Internal environmental management is closely related to green

information systems and both serve as an antecedent to the successful

introduction of green procurement, consumer engagement, eco-design and

investment recovery. Manufacturing companies must consider environmental

responsibility as a competitive priority before changing current information

structures to collect data and produce knowledge on environmental

sustainability programs and results. The first step in adopting GSCM activities

is to develop a corporate approach and to change current enterprise resource

planning (ERP) information structures to track environmental programs. The

second stage entails the introduction of renewable sourcing, collaboration with

clients, eco-design and investment recovery activities. The comparisons between

stage one and stage two of the practices are both constructive and important in

favor of the idea that the activities will be applied in phases.

Conclusion

As global warming increases and biodiversity improves, there is growing demand on companies to boost environmental efficiency. In addition, there is a rise in environmental consciousness among stakeholders, which allows companies to mitigate the negative environmental effect of firms’ activities. Green supply chain management (GSCM) has been described as an approach to optimizing the efficiency of systems and goods in compliance with the criteria of environmental legislation. While major barriers have been established to the GSCM adoption in the automotive industry are also discussed. The findings are carried out in order to investigate the complexities in a realistic way, as well as in a social context, the partnership of SSCM activity in businesses. A structure has been set up and attempts have been made in case studies to verify the structure. In particular, the implementation of sustainable policies and the functional performance of organizations in the supply chain administration were evaluated. In addition, a system-based methodology has been developed. Market competitiveness and uncertainty; lack of adoption of Green Practices; cost implications; lack of awareness of Consumers and Manufacturer Resistance to move in GSCM have been described as contingent variables. The research is intended to help incorporate environmental or ecological management of the supply chain to improve productivity on the world market. The biggest environmental challenge is the reduction in carbon emissions. The main aim of this study is to analyze and take a path to tackle the ecological aspects of supply chain management.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Conflict of Interest

The authors do not have any conflict of interest.

References

- K. Bhattacharjee, “Green Supply Chain Management- Challenges and

Opportunities,” Manag. Res., vol. 05, no. 01, p. 6.

- K. W. Green, P. J. Zelbst, J. Meacham, and V. S. Bhadauria, “Green

supply chain management practices: impact on performance,” Supply Chain

Manag. Int. J., vol. 17, no. 3, pp. 290–305, Apr. 2012, doi:

10.1108/13598541211227126.

- S. Ashraf, M. Gao, Z. Chen, S. Kamran, and Z. Raza, “Efficient

Node Monitoring Mechanism in WSN using Contikimac Protocol,” Int. J. Adv.

Comput. Sci. Appl., vol. 8, no. 11, 2017, doi: 10.14569/IJACSA.2017.081152.

- M. Hariga, R. As’ad, and A. Shamayleh, “Integrated economic and

environmental models for a multi stage cold supply chain under carbon tax

regulation,” J. Clean. Prod., vol. 166, pp. 1357–1371, Nov. 2017, doi:

10.1016/j.jclepro.2017.08.105.

- S. Ashraf, T. Ahmed, A. Raza, and H. Naeem, “Design of Shrewd

Underwater Routing Synergy Using Porous Energy Shells,” Smart Cities,

vol. 3, no. 1, pp. 74–92, Feb. 2020, doi: 10.3390/smartcities3010005.

- M. Igarashi, L. de Boer, and A. M. Fet, “What is required for

greener supplier selection? A literature review and conceptual model

development,” J. Purch. Supply Manag., vol. 19, no. 4, pp. 247–263, Dec.

2013, doi: 10.1016/j.pursup.2013.06.001.

- M.-L. Tseng, M. S. Islam, N. Karia, F. A. Fauzi, and S. Afrin, “A

literature review on green supply chain management: Trends and future

challenges,” Resour. Conserv. Recycl., vol. 141, pp. 145–162, Feb. 2019,

doi: 10.1016/j.resconrec.2018.10.009.

- S. Luthra, V. Kumar, S. Kumar, and A. Haleem, “Barriers to

implement green supply chain management in automobile industry using

interpretive structural modeling technique: An Indian perspective,” J. Ind.

Eng. Manag., vol. 4, no. 2, pp. 231–257, Jul. 2011, doi:

10.3926/jiem.2011.v4n2.p231-257.

- R. M. Grant, “Prospering in Dynamically-Competitive Environments:

Organizational Capability as Knowledge Integration,” Organ. Sci., vol.

7, no. 4, pp. 375–387, Aug. 1996, doi: 10.1287/orsc.7.4.375.

- S.

Ashraf, M. Gao, Z. Mingchen, T. Ahmed, A. Raza, and H. Naeem, “USPF: Underwater

Shrewd Packet Flooding Mechanism through Surrogate Holding Time,” Wirel.

Commun. Mob. Comput., vol. 2020, pp. 1–12, Mar. 2020, doi:

10.1155/2020/9625974.

- S.

Ashraf, A. Raza, Z. Aslam, H. Naeem, and T. Ahmed, “Underwater Resurrection

Routing Synergy using Astucious Energy Pods,” J. Robot. Control JRC,

vol. 1, no. 5, 2020, doi: 10.18196/jrc.1535.

- N.

P. Archer, “Supply chains and the enterprise,” J. Enterp. Inf. Manag.,

vol. 19, no. 3, pp. 241–245, May 2006, doi: 10.1108/17410390610658432.

- G.

Kannan, A. N. Haq, P. Sasikumar, and S. Arunachalam, “Analysis and selection of

green suppliers using interpretative structural modelling and analytic

hierarchy process,” Int. J. Manag. Decis. Mak., vol. 9, no. 2, p. 163,

2008, doi: 10.1504/IJMDM.2008.017198.

- S.

Ashraf et al., “Underwater Routing Protocols Analysis of Intrepid Link

Selection Mechanism, Challenges and Strategies,” Int. J. Sci. Res. Comput.

Sci. Eng., vol. 8, no. 2, pp. 1–9, Apr. 2020, doi: 10.26438/ijsrcse/v8i2.19.

- F.

Lettice, C. Wyatt, and S. Evans, “Buyer–supplier partnerships during product

design and development in the global automotive sector: Who invests, in what

and when?,” Int. J. Prod. Econ., vol. 127, no. 2, pp. 309–319, Oct.

2010, doi: 10.1016/j.ijpe.2009.08.007.

- A.

Jean-Vasile, Ed., Food Science, Production, and Engineering in Contemporary

Economies: IGI Global, 2016.

- Y.-F.

Wang, S.-P. Chen, Y.-C. Lee, and C.-T. (Simon) Tsai, “Developing green

management standards for restaurants: An application of green supply chain

management,” Int. J. Hosp. Manag., vol. 34, pp. 263–273, Sep. 2013, doi:

10.1016/j.ijhm.2013.04.001.

- X.

Chen and G. Xiu, “Research on the Degree of Ecological Supply Chain Management

Practice among Chinese Manufacturing Enterprises,” J. Qual. Reliab. Eng.,

vol. 2014, pp. 1–5, 2014, doi: 10.1155/2014/160957.

- S.

Mahapatra, R. Pal, T. Hult, and S. Talluri, “Assessment of Proactive

Environmental Initiatives: Evaluation of Efficiency Based on Interval-Scale

Data,” IEEE Trans. Eng. Manag., vol. 62, no. 2, pp. 280–293, May 2015,

doi: 10.1109/TEM.2015.2413938.

- M. A. Sellitto, J. Luchese, J. M. Bauer, G. G. Saueressig, and C. V. Viegas, “Ecodesign Practices in a Furniture Industrial Cluster of Southern Brazil: From Incipient Practices to Improvement,” J. Environ. Assess. Policy Manag., vol. 19, no. 01, p. 1750001, Mar. 2017, doi: 10.1142/S1464333217500016.

This work is licensed under a Creative Commons Attribution 4.0 International License.

, Tauqeer Ahmed1

, Tauqeer Ahmed1 , Sehrish Saleem2

, Sehrish Saleem2 and Zeeshan Aslam3

and Zeeshan Aslam3