Muhammad Arif Bin Jalil

Physics Department, Faculty of Science, Universiti Teknologi Malaysia, UTM, (Malaysia).

DOI : http://dx.doi.org/10.13005/ojcst/10.02.01

Article Publishing History

Article Received on :

Article Accepted on :

Article Published : 09 Jun 2017

Article Metrics

ABSTRACT:

This study presents the modelling, simulation, and characterization of the Fiber Bragg grating (FBG) on maximum reflectivity, bandwidth, the effect of applied strain to the wavelength shift, ʎB and sensitivity of the wavelength shift with strain for optical sensing system. In this study, a commercial FBG with the center wavelength of 1550nm is used in order to measure the spectral response of FBG to strain. The parameters used in these simulations are the fiber grating length, L ranging from 1 to 10mm, the changes in refractive index, ∆n from 0.0002 to 0.0020, the effective refractive index, is 1.46 and the grating period of FBG,Λ for 530nm in the performance of FBG. The bandwidth and spectrum reflectivity are analyzed from the variation of refractive index and grating length. Simulations on the FBG are carried out using OriginPro 2016 and Microsoft Excel 2010 software. The Excel sheet is used to generate data and the OriginPro 2016 is used to generate the graphs. The results obtained indicates the variation in grating length and refractive index affect the spectral reflectivity and the bandwidth. In addition, results obtained show that the changes in the Bragg wavelength are due to an increase in length of the grating region which due to the applied strain.

KEYWORDS:

Fiber Bragg Grating; Optical Sensor; OriginPro Software; Strain; Maximum Reflectivity; Bandwidth

Copy the following to cite this article:

Jalil M. A. B. Modeling and Simulation of Fiber Bragg Grating (Fbg) as A Strain Sensor. Orient.J. Comp. Sci. and Technol;10(2)

|

Copy the following to cite this URL:

Jalil M. A. B. Modeling and Simulation of Fiber Bragg Grating (Fbg) as A Strain Sensor. Orient. J. Comp. Sci. and Technol;10(2). Available from: http://www.computerscijournal.org/?p=6032

|

Introduction

Over the past few years, there are various components related to the industries were developed for fiber optics sensing systems. The advantages of optical fiber sensors include high sensitivity, low power consumption, wider bandwidth, and immunity to electromagnetic radiations gives wide-ranging applications in places where conventional sensors are unable to operate appropriately or not suitable with the environment involved. Throughout this study, several characteristics of FBG as an optical sensor are presented and discussed: The Bragg wavelength shift, bandwidth of full-width at half-maximum (FWHM), reflectivity, and the changes in index of refraction. An FBG has a structure of weak coupled waveguide and the coupled-mode theory can be used in this study to analyze the propagation of light in optical fiber. Fiber Bragg grating has lightweight, compact size and large bandwidth. Thus, it is suitable to be used in strain and temperature sensing applications. The main benefits includes accurate positions in the fiber and easy to manufacture and calibrate.

Methodology

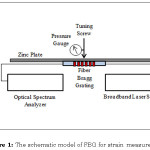

From Figure the FBG model system consists of a commercial FBG, an optical spectrum analyzer (OSA) as the detector, a broadband laser source, an optic cable to connect the FBG to OSA and laser source, a zinc plate, and a pressure gauge. The specification of the commercial FBG used in this study is given in Table 1.

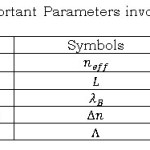

In this study, a uniform FBG sensor model is being simulated with using OriginPro software in order to obtain the spectral response. The parameters involved in the simulation of spectral responses are as listed by Table 1.

Results and Discussion

Shift in Bragg’s Wavelength

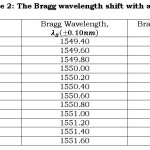

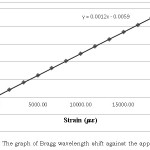

From the calculated data in Table 2, a graph of shift in the Bragg’s wavelength against the strain applied is plotted and is shown in Figure 2 below.

Spectral Reflectivity

|

Table 3: Variation of reflectivity (R) with the variation of grating length (L) and changes in index of refraction (n)

Click here to View table

|

From Figure 3, the reflectivity increases with the rising of grating length. The FBG obtained 100% reflection when the length of grating, L reach 7 mm while the changes in index of refraction, increase to 0.0004. In addition, this value is maintained for longer length of grating and higher variation in index of refraction shown by Table 3.

|

Figure 3: The impact in the variation of grating length (L) and refractive index ( ranging from 0.0002 to 0.0010 on reflectivity, (R)

Click here to View figure

|

|

Figure 4: The reflectivity spectrum of a uniform FBG with different value of grating length at constant change inrefractive index of

Click here to View figure

|

A graph of reflectivity versus wavelength for different grating length are shown in Figure 4. From the graph, it is clearly shown that the increase of grating length causes the increase in reflectivity which is highly desirable for reflection of FBGs.

Conclusion

For conclusion, the bandwidth and reflectivity spectrum were obtained with the changes in length of grating and variation in refractive index. Furthermore, the efficiency of the FBG as a strain sensor was determined. From the simulation results, the increment of grating length and refractive index increases the reflectivity. The bandwidth of FBG decreases by increasing the grating length and it increases by increasing the refractive index change. The sidelobes of spectral reflectivity can be suppressed by apodization of Gaussian profile technique by using OriginPro software.

Acknowledgements

The author would like to thank the Ministry of Higher Education of Malaysia (MOHE) and UTM for providing GUP Tier 2 (2016/2017) grants in order to conduct this research and developing the paper.

References

- Fahd Chaoui, O.A., Mounia Chakkour, and Mounir El Yakhloufi, Apodization Optimization of FBG Strain Sensor for Quasi-Distributed Sensing Measurement Applications. 2016.

- Son2, J.-W.K.a.Y.-H., Thermal Characteristics of Temperature Sensor Using Fiber Bragg Grating for Optical Sensor Network Communication. 2013.

- E. Gemzický, J.M., Analysis of simulated reflection characteristics of uniform and apodized fiber bragg gratings. 2008.

- Salo, J. and I. Korhonen, Calculated estimate of FBG sensor’s suitability for beam vibration and strain measuring. Measurement, 2014. 47: p. 178-183.

CrossRef

- Jin, W., et al., CHAPTER 25 – Structural Strain and Temperature Measurements Using Fiber Bragg Grating Sensors A2 – Pal, Bishnu P, in Guided Wave Optical Components and Devices. 2006, Academic Press: Burlington. p. 389-400.

CrossRef

- Pereira, G., et al., On the improvement of strain measurements with FBG sensors embedded in unidirectional composites. Polymer Testing, 2013. 32(1): p. 99-105.

CrossRef

- Salo, J. and I. Korhonen, Calculated estimate of FBG sensor’s suitability for beamvibration and strain measuring. Measurement, 2014. 47: p. 178-183.

CrossRef

- Nagwan I. Tawfik1, W.S.E., M. B. El_Mashade3, A. E. Abdelnaiem2, Optimization of Uniform Fiber Bragg Grating Reflection Spectrafor Maximum Reflectivity and Narrow Bandwidth. 2015.

Views: 1,829

This work is licensed under a Creative Commons Attribution 4.0 International License.