QoS Priorities in ERP Implementation – A Study of Manufacturing Industry of Nepal

Introduction

In this rapid changing world,

economy has amplified the demand for corporations for supplying the merchandise

a lot of swiftly and with better quality whereas decreasing prices to get high

consumer satisfaction. For transitory relief regarding hike in costs can only

be fixed by downsizing, outsourcing, etc. To run in the race of competition,

many of the organizations are making their advance level work process with

proper decision from top management committee. Different sized organizations

whether it be top grade or mid-size organization they are involving in adopting

latest ERP software having broad-minded investments.

ERP is such a system which helps

business process in terms of well-designed software with proper integrate

within different departments and branches which incorporates HR, monetary,

financial, sale & supply, project & material management, SCM, QM

(Shehab, Sharp, Supramaniam, & Spedding, 2004). Manufacturing defines a

process of remodeling fresh materials to polished merchandise available. It

covers the assembling process with assimilation of specified parts for better

product (Blanchard, 2012). Firms should use latest information technology for

continuous support with enhancement in business process leads to compete in

rapid changing world. For managing organizations in terms of information, ERP

has become the latest system of PC tools with excellent features. It combines

the processes, information among different units also with different

functionalities, branches, companies and also with any geographic locations.

Quick response, on-time delivery, inventory management, interaction between customer

and suppliers are some of the advantages of ERP. (Gupta & Kohli, 2006)

explained their view saying “ERP adopts business processes in the

decision-making process and integrates all the useful components of a company,

sales, marketing, production, operations, logistics, purchases, finance, new

developments and human resources.” It helps good electronic commerce facility

whic h ensures proper business growth with great level of client service and

good productivity applying less inventory & price (Su & Yang, 2010).

ERP of manufacturing companies has

encountered a series of challenges that affect the pursuit of business

objectives including operational strategic positioning and effectiveness.

National Association of Manufacturers (NAM, 2011) patent the need for available

skilled labor are vacant as nearly 5% of all manufacturing jobs and 82% of all

manufacturers have a shortage of skilled production workers. Untimely and

fragmented communication among higher management, employees, and different

stakeholders contributes to fade productivity and method inefficiencies yet.

Sufficient training and education (TED) will maximize the performance of

workers by reducing the time needed to find out and operate new systems,

however, because of restricted budgets and resource concerns, corporations are

usually forced to solely part fulfill coaching desires. The implementation of

ERP makes significant changes to the management of business processes. ERP

implementation makes modification in business process board. Top management

commitment in ERP implementation and equal effort is required for effective

system.

For successive variations in the

market many organizations are performing highly advanced agility work to

enhance capability by changing and modifying verdict making process. During

last few decades, a large number of corporate firms and organizations used ERP

system in order to expand further as technology takes a hike (Karim, 2011).

ERP’s systems area unit designed with the hunt to boost productivity by

enhancing associate organization’s ability whereas generating correct and

timely info across the enterprise, and everyone its offer chain. The productive

ERP systems implementation will result to lower inventories, cut back

development cycle, improve client service, increase potency (productivity),

improve gain and improve effectiveness through higher client services (Beheshti

& Beheshti, 2010).

Researchers have developed different

success model (such as ERP) information systems. After verifying different

models, DeLone and McLean are the best choice model by many researchers. A

study was conducted by DeLone and McLean on IS success representing qualitative

behavior of it, user interaction to information systems (user satisfaction),

consumption of the output (use), impact in organization & impact on

individual (Bernroider, 2008). As a result, it was demonstrated inconsistent

empirical results with one another.

In a competitive era, there is

required of new product having some modification than older one within less time

frame which are making many corporations under pressure to shift demand.

Similarly, launch of new products is increasing complexity to industries. Due

to different functionality and working module of an organization it has become

difficult to coordinate with other organization (Gattiker, 2007). There are

numerous ways to respond to manufacturing companies. First response, to

increase inventory buffer and capacity (Thompson, 1967) (Pagell, Newman, Hanna,

& Krause, 2000). The second response, to make easy with production and

other processes (Sakakibara, Flynn, Schroeder, & Morris, 1997). (Hauptman

& Hirji, 1996) suggests the third one which relates to increasing

integration. In Manufacturing-Marketing (MM) interface, ERP delivers large

payoffs which answer how and where issues.

Background of the Study

In the 1990s, the term ERP was used

for the first time, capable of dealing with other commercial functions such as

finance and accounting, engineering. Management of human resources and

projects, etc. In 1940’s its history began by using calculating machines for

business. In 1960’s applications were introduced that can easily control and

handle inventory management. IT partner IBM & J.I. Case (tractor

industrialist & other manufacture machines) performed combined effort which

further created software named as Materials Requirements Planning i.e. MRP

(Joshi, 2017).

Varieties of elements are

incorporated in ERP software package i.e. economics and production, human

resources, sales, integration of data depending upon business processes also it

can be customized on-demand or specific needs of an organization. ERP system

allows sharing databases in different business units with different orientation

depending upon divisions like accounting and sales uses same information for

their needs (Esteves & Pastor, 2001). As ERP software offers some ways of

synchronizing report and automation. To understand the performance of the

business environment, dashboard is the primitive feature of ERP which helps to

quick overview of current business situation. To acquire high market place, an

enterprise needs to perform work actions in Data Quality. Data Quality (DQ)

uses dimensions for better quality are completeness, instance accuracy,

accessibility and timeliness (Rothlin, 2016). Data Quality problem is one of

the difficult portions to be handled by organization which generally occurs due

to Data errors i.e. Conceptual (design) and Operational problem.

Problem Statement

Most of the manufacturers put hard

effort to follow complex processes for increasing overall productivity and

profitability which makes idea of great profit with time but streamlining

long-established processes can be time-consuming endeavor and daunting. From

the beginning, precise quality programs and new technologies are placed by

manufacturers properly so that it makes easier for them to improve processes

& get sudden benefits.

Lack of ERP system quality has a

high risk to get employee satisfaction in the business world. Before releasing

the ERP system many companies usually conduct different continuous tests.

Normally ERP companies have spent lots of time testing and debugging.

It’s a huge disadvantage for

companies to test the system using project budgets (Rothlin, 2016). Critical

ERP implementation, testing, and volume occupy nearly 50% of the total ERP

budget due to lack of Quality Assurance and Quality Control methods.

Research Questions

How ERP is helping the manufacturing

industry to manage and support the value creation of product?

What is the efficiency of the ERP

system in terms of quality?

How is the service provided by ERP?

Purpose of the Research

This research relates to a different

aspect of Quality of Services in terms of ERP implementation especially in

Manufacturing Industry of Nepal. It also helps to find out the acceptance of

good productivity as claim by ERP support team. This research aims to find out

the gaps and challenges while using ERP with its pattern in manufacturing

industry in Nepal.

Objectives of the Research

Successful ERP system implementation

maintains standardization of product which achieves high quality. Continuous

Quality Controlling and Quality Assurance methods help to maintain standard

quality (Arachchi, Chong, & Madhushani, 2015). ERP systems face failures,

risks because of no proper testing, tangibles, conformance, assurance,

responsiveness, courtesy, serviceability, reliability, etc. This survey is

going to identify on the following basis:

To understand the current ERP usage

in the manufacturing industry of Nepal.

To find the challenges of ERP

implementation in the manufacturing industry.

Scope and Limitation of the Research

The scope of this research is to

find the gap of using ERP system between different manufacturing industries of

Nepal. The main motive for this research is to look after different ERP system

usage feedback by different manufacturing industries i.e. Cigarette factory,

Noodles & Alcoholic Factory, Herbal Factory, etc.

Implication of the Research

This research aims to find the

difficulties performed before and after ERP (Enterprise Resource Planning)

system implementation. Also, to evaluate the different quality of service

priorities after ERP implementation. The research tends to result in a

beneficial choice of ERP system, especially to the manufacturing industry.

Research Design and Methodology

Research Methodology

It is viewed as one of the leading

research tools. It indulges research approach, research strategy, philosophies

of research methodology, time limit and choice. The research onion of

(Saunders, Lewis, & Thornhill, 2007) is to be formulated for giving

comprehension of the research methodology which is going to be used in dissertation. Ontological,

epistemological and axiological research are the methodological choices which

is to be kept in mind while doing research. In this chapter, we will talk about

the research philosophy, approach, strategy, data collection and analysis

techniques which were utilized in this research.

Research Plan and Design

To carry out this investigation, a

descriptive and explanatory investigation is carried out. This research is

mainly evaluated based on a primary survey. An expert suggestion on the need

for research was considered exceptional for the questionnaire. The study is

based on several statistical tests such as correlation, regression, average,

standard deviation, among others. The software called Statistical Package for

Social Sciences (SPSS) and Microsoft Excel was used to analyze and interpret

quantitative data. This software is commonly used by researchers easily

available in a corporate environment. Scale reliability is analyzed using

Cronbach’s alpha since Cronbach’s alpha test is the best fit for multi-scale

articles and is also the most popular test for reliability of consistency

between articles.

Research Approach

Different procedures took to conduct

the research which is the primary concern of the research approach. The

existing approaches i.e. deductive and inductive which will be helpful while

conducting research. The first approach is inductive by collecting data based

on the method of findings and observations which is relevant to the topic.

Research Strategy

(Saunders, Lewis, & Thornhill,

2007) says that the research strategy incorporates the survey, case study,

experiment, grounded theory, action research, ethnography and lastly archival

research. Each method data is combined and inspected from one approach then

onto next. Each and every research strategy can be connected to each other

where all can be easily explainable. Combination of both qualitative and

quantitative approaches with new statistical tools are frequently increasing

strategic management. Qualitative data enrich and colors the analysis and

interpretation of such phenomena whereas quantitative data attracts the

underlying objective facts that give evidence of the phenomena

(VARGAS-HERNÁNDEZ, LEÓN, & VALDÉZ, 2011).

Data Collection

Sampling Methods and Sample Design

A superiority is given to primary

data collection method in this research. This type of data is firstly used for

testing assumption and after that helping out to support researcher privilege.

For the support of primary data, researcher can use secondary data as per

required.

A survey method was approached for

the study of vivid research. To get quantitative data, the result obtained from

collected questionnaire were administered. For the mode of administration, both

paper based & e-survey methods were formulated. In paper-based survey,

researcher personally visits and provides the respondents a hardcopy of the

questionnaire. Using internet as a mediator a survey was conducted where the

questionnaire links were sent to respondents.

The objectives of the research

guided the overall survey and study as objectives are mentioned in the

beginning of the chapter. The respondents were directly related to the ones who

use ERP system. The age band of 20 to 50 years above. Therefore, the level of

understanding of the respondents was considered during the sample design. The

researcher distributed one hundred and fifteen (150) online questionnaires to

the interviewees, of which one hundred and fifteen (115) responded, while the

same survey was distributed manually to seventy (70) people and only fifty-two

(52) responded. In total, one hundred and sixty-seven (167) people responded to

the survey of two hundred and twenty (220) sent to answer.

Data Collection Methods

With the help from literature, web

engines, papers, and views through questionnaires as filled up by officials

& staffs of manufacturing industries & public for adopting the plan

primarily.

Primary & Secondary data are the

2 different sources for the collection of data.

Data Capturing and Data Editing

Primary Data

Using subsequent techniques primary

data will be collected:

Questionnaire

Well-structured questionnaire for

executive, manager, and employee of manufacturing industry will be prepared.

The questionnaire includes the questions regarding quality of services provided

after ERP implementation which incorporates service, feasibility, adaptability,

changeability and so on in manufacturing industries of Nepal.

Interview

The interview will be conducted with

the executives, managers, and employees of manufacturing industry of Nepal to

understand the views in details.

Observation

For better understanding, a running

system will be observed on the site visits of the manufacturing industry of

Nepal. The participation of the officers, employee, and public in actual

implementation of the system, will be observed. The concrete pros and cons of

the system will be deeply observed.

Secondary Data

From the following sources it has

been taken help for collection of secondary data:

Reference Books

The researcher will study various

books and references related to ERP implementation in the manufacturing

industry, Enterprise Resource Planning Systems and User Performance, Quality

Assurance and Quality Control in ERP Systems Implementations, An Information

Processing Theory View of ERP, Critical success factors in the implementation

of ERP system, etc.

Journals & Research Papers

Various journals and research papers

will be referred.

Internet Source

Internet sources will be viewed for

better understanding about benefits, framework, working principle, procedure,

features, Business operations, etc. of ERP especially in the manufacturing

industry all over the world.

Design of the Interview and questionnaire question

To the respondents, a well-designed

questionnaire was prepared and shared. As mentioned instructions, respondents

filled up the questions. After the completion of questionnaire, it was

collected from them. Very less time will be taken to fill up the questionnaire

as it contains closeended questions. For the easiness to response the answer

without any biasness the questions were mostly measured using 6 rating i.e.

Likert Scale (1(strongly disagree) to 6(strongly agree), with disagree, and

agree as interval points) and also with Yes/No options.

Data Collection Limitation

During the interview, the

interviewee would provide an answer based on his/her experience and knowledge

which might be biased.

When using the questionnaire, the

participants are restricted to the options given in the questionnaire.

Also, when using the questionnaire,

the answers might not be fair enough if the correspondence is an influence.

Data Collection Assumptions

The participants are randomly chosen

to represent the entire manufacturing industry of Nepal.

The participants are primarily

chosen especially with IT background with related minimal knowledge to the

research domain.

Reliability and Validity

Research validation in regard of

design and plan are verified with discussion of experts also, before taking

startup to investigation portion there was the development and tested the

research instrument. With the discussion of my supervisor, questionnaire was

formed. In consider with research

question, all the items were properly designed. To find out correctness of data

both reliability and validity are incorporated. A true measurement which

represents characteristics refers to validity. Some samples will be collected

to measure exterior validity. To grasp the customer’s perception with maximum

content validity there were performed comprehensive literature review.

Reliability refers to item, scale or instrument correlation with a hypothetical

one which measures what it is supposed to be. P-value is compared in terms of

0.01. If p value is less than 0.01, the null hypothesis is rejected else if it

is equal to or more than 0.01, the null hypothesis is accepted. Means were also

compared to assess the reliability of scales. The value ranges between 1 to 6

and the mean is 3.5. Generally, it is thought that the mean value more than 3.5

is positive response, the mean value 3.5 means adequate and less than 3.5 is

negative response. The values are if above 3.5 it can be concluded that the

scales are reliable.

Limitations

There were some limitations during

data gathering and analysis process. One of the limitations was that it was too

difficult to get full participation, as most of the participants did not fill

up the questionnaire. The original time planned for data gathering was one

month but due to some unforeseen reasons, the data collection took more than one-month

time period.

Research Timeframe

There are only two types of research

timeframe i.e. longitudinal or cross-sectional timeframe whereas longitudinal

timeframe is useful for those research which takes much longer period but it

quite different with cross-sectional timeframe i.e. it is useful for those

research that takes a limited timeframe. A longitudinal study is additionally

associate empiric analysis technique that gathers knowledge for identical

subjects repeatedly over an amount of your time because it will extend over

years or even decades (Rouse, n.d.). The cross-sectional study design allows

researchers to compare different variables at the same time as looking at

gender, age, income, and educational level. It may not provide definite information

about cause and effect relationships (Institute for Work & Health, 2019).

The timeframe which is allocated for the research to be carried is actually

research timeframe. It gives time for gathering data and what must be achieved.

Only for gathering data exercises will not be more than 21 days. If there is a

delay in data gathering, the result would be matched against total expected

result and once the participant limit covers 75% feedback, then it means your

data is valid and can be used without waiting for remaining feedback result.

Ethics and Confidentiality

Ethics and confidentiality is a very

careful portion which is important to state the reason why a particular data is

to be collected. Safety of each data becomes very important whereas confidentiality

involves keeping data safely after gathering from a group of people where no

other can have access to it. For the purpose of this research, different data

were collected from varied manufacturing industry and kept safely as

confidentiality. All the collected data were utilized for the purpose of

research and no other purpose. Being trustworthy, no data were shared with any

person, group or organization. All of the participants were clearly informed

and explained why such information is being collected and for what purpose it

is used for.

Data Analysis And Findings Of Research

Mode of Analysis

Quantitative data analysis methods

were usually used for questionnaire data analysis which was utilized to analyze

statistical data and after that collection of interview data was done. A

researcher essential portion is to analyze and interpret data that relates to

modifying data which explains the solution to the research question. For the

data, both the analysis i.e. qualitative and quantitative approaches are going

to help for achieving (Akande, April, & Belle, 2013). There are different

tools available for analyzing the quantitative data i.e. SPSS, MATLAB, PSPP,

Microsoft Excel, Google Analytics, Stata, etc. Semiotics, hermeneutics,

narrative and thematic analysis are different modes available for analyzing the

qualitative data. To analyze & interpret the data, Statistical Package for

social science (SPSS) and Microsoft Excel are the software which was used.

Commonly researchers use this software as it is easily available with business

setting. These tools were very fruitful and useful throughout the data

transcription and habituation.

Overview Analysis of Questionnaire

Results

Questionnaire Duration

Each questionnaire duration was of

thirty (30) minutes and the participants.

Profile of Participants

For the questionnaire, the

contributors were from the manufacturing industry and some expertise from IT

industry, which has the knowledge of ERP whereas employees of manufacturing

industry were not filtered with specification of departments.

Number of Participants

Online survey and manual

distribution survey was carried out which was made accessible and available for

the participants. The researcher distributed one hundred fifty (150) online

questionnaires to respondents out of which one hundred and fifteen (115)

responded whereas the same survey was also distributed manually to seventy (70)

individuals and only fifty-two (52) responded to it. In total one hundred and

sixty-seven (167) individual responded to the survey out of two hundred and

twenty (220) send for response. The validity for use was set more than 75% for

better accuracy. The result is given below.

Analysis

The analysis is necessary to find

the gap of ERP implementation in different manufacturing industry also with the

services are as the vendor has promised them. The questionnaire is usually used

to get an opinion from different sectors of individual especially in

manufacturing industry regarding ERP. It also lets participants share their

feeling about ERP as they are always the prospective user. Altogether there are

Forty-seven (47) questions out of which only twenty-five (25) questions are

structured below.

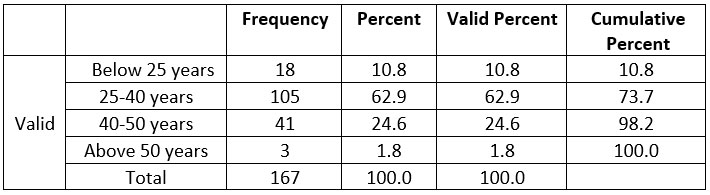

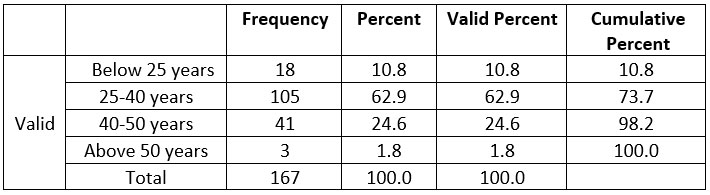

Table 1: Age Frequency

In this research, it has been found

that most of the participants i.e. 105 in the survey is of 25-40 years range

which is 62.9% all of the total 167 whereas 24.6% respondent of age range 40-50

years, 10.8% of age below 25 years and lastly 1.8% respondent of age above 50

years.

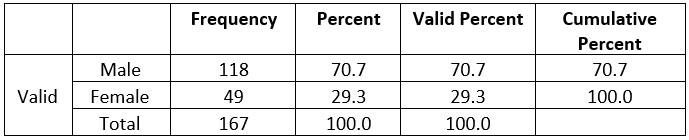

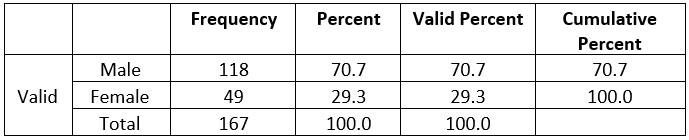

What is your gender?

Table 2: Gender Frequency

The table clearly shows that out of

total of 167 respondents, 118 were categorized under Male field with 70.7% of

total participants whereas 49 respondents were categorized under Female with

29.3% of total participants. To represent the data more clearly graphical

representation of gender-wise distribution is shown above.

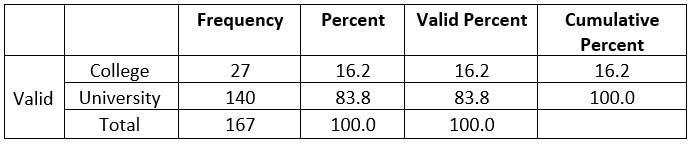

What is the level of your education?

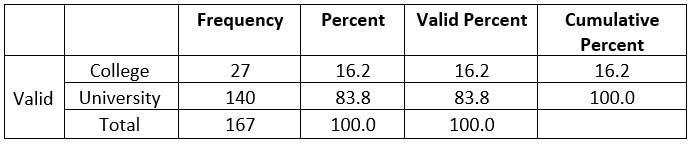

Table 3: Level of Education Frequency

According to the survey, most of the

respondent is of University level which might make the result more effective.

As 140 respondents have University level education whereas the remaining 27

respondents have got the knowledge of College level education.

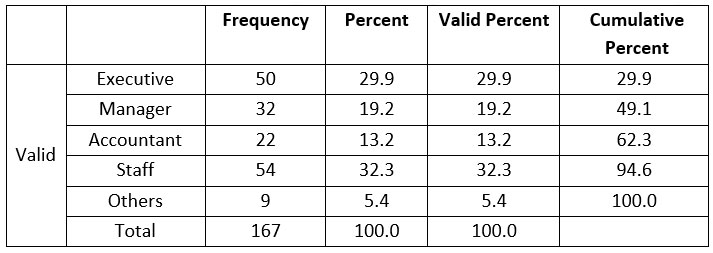

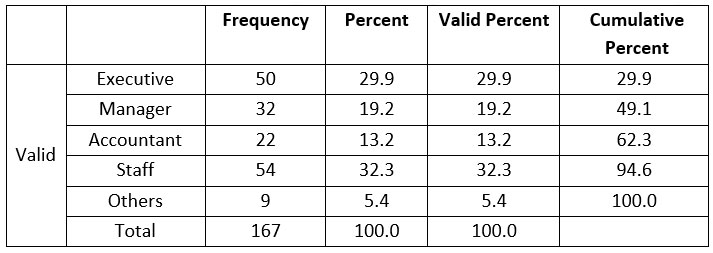

What is your position?

Table 4: Position Frequency

We have a variety of position and so

some are listed accordingly as common. Hereafter in the survey, out of 167

total participants 54 respondents were staff i.e. 32.3%, 50 respondents were

executive i.e. 29.9%, 32 in total respondents were manager i.e. 19.2%, 22

respondents were accountant i.e. 13.2% and ending up with 9 others position

employee with 5.4% respondent. In the survey, we have similar frequency of two

different positions which has absolutely different roles comparing together

i.e. Executive and Manager, this might help to get different perspective from

both the sides which might make me easier to get with objectives.

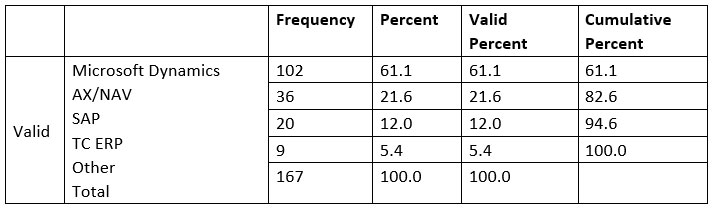

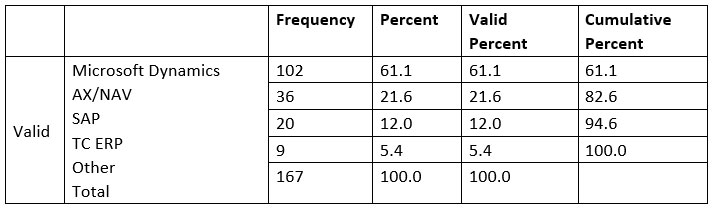

What type of ERP system are you using?

Table 5: ERP system Frequency

Different ERP software were listed

out to the respondents, whereas most of the manufacturing industry uses

Microsoft Dynamics AX/NAV i.e. 102 respondents choose this system i.e. 61.1%,

SAP (Systems Applications and Products) system were chosen by 36 respondents

i.e. 21.6%, TC ERP by 20 participants and other system by 9 respondents.

Looking after the result, most of the manufacturing is dependent upon Microsoft

Dynamics AX/NAV.

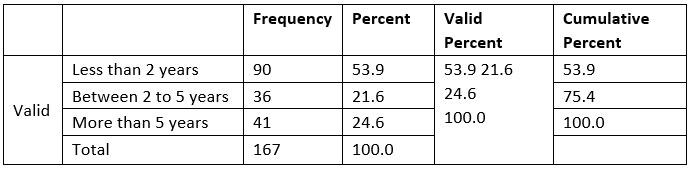

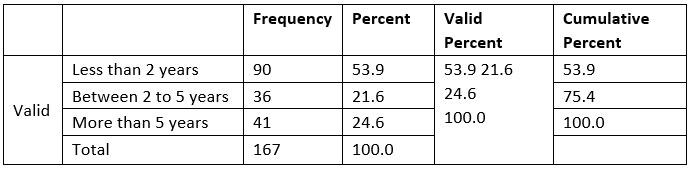

What is your work experience with the ERP system?

Table 6: Work experience Frequency

In the above table result, it can be

seen that 90 respondents i.e. 53.9% out of total 167 have less than 2 years’

experience with the ERP system, similarly, 41 respondents have more than 5

years’ experience and 36 respondents have the experience in between 2 to 5

years’. An emerging technology requires the individual to get updated rapidly

as the number of respondents is higher who has less than 2 years’ experience

regarding ERP makes them know about system efficiently with changing features

to the system.

Analyzing ERP usage pattern

The SAP ERP versus Dynamics

Comparison Report facilitates the work of examining the first variations

between the 2 software system, however solely with reference to

characteristics. For that reason, your comparison chart does not account for

your group’s priorities, no matter the result they may wear the ultimate

outcome. This ought to be thought of should your organization need to perform a

lot of thoroughgoing comparison method. The subsequent features and

functionalities are listed below:

Economic

Humanoid Resources

Manufacturing Management

Record Management

Procuring Management

Superiority Management

Deals Management

Merchandise Technology

Let’s take a closer look at each of the eight

domains.

Economic

SAP ERP is appreciated because

comparing with Dynamics it is powerful contender in terms of features and

functions of economic.

Human Resources

According to some study, SAP is

found with high ranking than Dynamics. In terms of Humanoid Resources options

and functions that area unit offered off the shelf as SAP has also excelled in

it.

Manufacturing Management

Both SAP ERP and Dynamics offer

comparable coverage of Manufacturing Management functions and features.

Inventory Management

SAP ERP slightly eclipses Dynamics

in terms of Inventory Management features and functionalities.

Purchasing Management

The two software supply similar

coverage of buying Management options and functionalities; they each give

comparable coverage of capabilities during this module.

Quality Management

Again, neither software stands out

here. Both Dynamics and SAP ERP have nearly the same support for Quality

Management features and functions.

Sales Management

SAP ERP slightly outperforms

Dynamics in the Sales Management module.

Merchandise Technology

In this field, we have found that

SAP obtains higher rating than Dynamics. Here we see that SAP ERP excels with

regard to functionalities that are available off the shelf (Technology

Evaluation Centers, n.d.).

Overview Analysis of Interview Results

Interview Duration

As due to the busy schedule of

interviewees there was a time limitation which was almost an hour for each

interview. The participants were allowed to answer the questions in an open way

in order to avoid the researcher from influencing the response coming from the

participants.

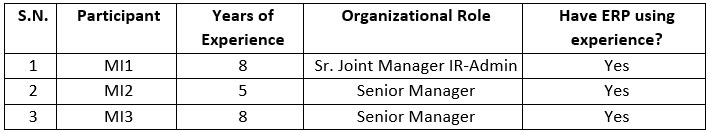

Profile of Interview Participants

All the participants were from the

IT perspective of their respective manufacturing industry.

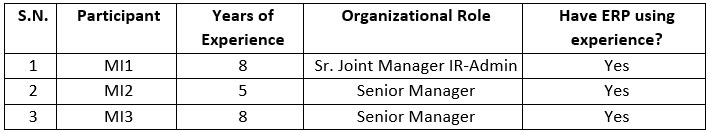

Below table represents the

participants’ role and years of experience. This research refers to

participants as MI1 and MI2 in order to ensure their confidentiality and that

of their respective manufacturing industries. Starting from three (3) years to

ten (10) years are the experiencing years by participants which makes them

involve with IT decision in their own manufacturing industries.

Table 7: Tabular form of Interviewee details

Sample questions to Interviewee

Below few questions are extracted as

a sample question which will be asked to the interviewee.

What are the challenges faced during implementation of an ERP?

Do you feel any changes in productivity after ERP implementation?

How effective services are provided by an ERP vendor?

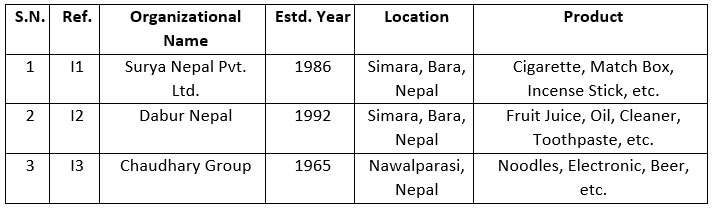

List of visited industries

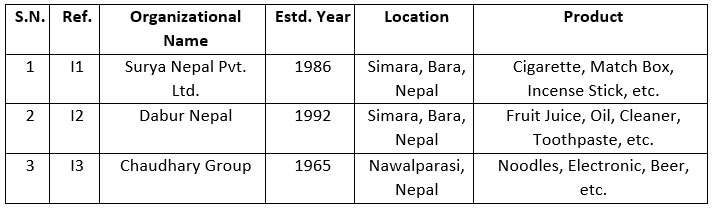

The below list are of different

manufacturing industries where the researcher visited for it survey and

findings.

Table 8: Tabular form of visited industries

Number of Employees

The manufacturing industries where

the respective participants work are all large and famous in Nepal and in other

countries with ranging employees from 500+ to 5000+. The manufacturing

industries are referred to as I1, I2 and I3.

Participants by Role in IT Decisions

All the participants from the

manufacturing industries are involved in making IT decisions for their

respective workplace.

Participants understanding of ERP

Understanding of ERP by

participants, all of them have very good knowledge of ERP and were able to give

their view of ERP based on their experience. Some of the definitions of ERP by

the participants are:

According to MI1, “This software

package makes selections easier as a result of the integrated information is accessible

with slightly.”

According to MI2, “Tons of apps to

add and configure that makes the possibilities endless for what does and can do

to help our business grow and grow our business in the right direction with its

gorgeous visual charts and widgets and knowledge management.”

According to MI3, “ERP is very

versatile platform to make worldwide and standardized MES template”.

Data Findings

Technology

Security

It is the most essential factor to

consider when adopting ERP system, particularly for manufacturing industries.

The system holds the sensitive and confidential data of customers, employees,

and product. There are other more things to consider depending on the use case

as said by some participants. Some participants noted that cost and quality of

internet services are important for conduction of business activities. An

example gave by one participant was the need for continuous connection is

required for branch interconnection and for tracking products. Commonly,

security terminology was repeated by most of the participant several times

which show security is the most significant factors for manufacturing industry.

Architecture

The architecture of the ERP system

in some manufacturing industries are three-tier architecture and some have

web-based architecture. MI3 stated that they have their own local data center

for storing data with their functioning for the purpose of failover and to

minimize the downtime.

Quality of service

Quality of system specification and

Internet services are very important for ERP system to function effectively as

the ERP system requires a good processor with system compatible operating

system and some manufacturing industries requires good Internet service for its

reliability.

Organization

Impact on business value

Many respondents have agreed

regarding cultural change while ERP implementation. In terms of the business

value of ERP implementation, all of the participants have defined as essential

and measured with growth of production as well as satisfaction.

Skills

and Training

Proper understanding of system use

is one of the most essential parts for effective result. As ERP system is one

of the complex systems which requires trained staffs and expertise in computer

in terms of department wise. MI1 says for continuous improvement in

organization growth there should be skilled manpower and can be sharpened more

by training.

Business

Continuity and Disaster Recovery

ERP software provides disaster

recovery in itself with the features of time-time backup. Every ERP system has

its own plan and thought for recovering data from disaster. MI1 noted that

before deploying ERP in particular place you need a full documented business

continuity and disaster recovery plan. Quick recovery is essential as in many

organizations they don’t have any ability to do business without ERP working

smoothly (ERP Desk, 2015). Contingency plans required if primary disaster

recovery plan fails and also documentation need to cleared regarding whom to

contact when such disaster event occurs said by MI2.

Environment

Cost

Total cost estimation of an ERP

software solution requires careful asses manufacturing industry, not of an

array of variables which may vary widely from one organization to another

(WorkWiseSoftware, 2013). In terms of cost determination, it may also vary

based on unique requirements and the scope. Understanding the factors i.e.

maintenance, training, software customization, upgrades, support, process

redesign, etc. that will influence the cost of ERP. It will also help to get

better idea of business which can be paid as expected. Some participants said

that cost is very important as their goal is to spend less amount where

possible and believe to deliver the same or better quality of work.

Conclusions and Recommendations

Findings

To

understand the current ERP usage in the manufacturing industry of Nepal.

In the research, we have found that

neither software stands out here. Both Dynamics and SAP ERP have nearly the

same support for Quality Management features and functions. Both SAP ERP and

Dynamics offer comparable coverage of Manufacturing Management functions and

features.

One of the supreme significant

question which is the startup objective regarding current research. Different

ERP software were listed out to the respondents, whereas most of the

manufacturing industry uses Microsoft Dynamics AX/NAV system. Looking after the

result, most of the manufacturing is dependent upon Microsoft Dynamics

AX/NAV.

To find

the challenges of ERP implementation in the manufacturing industry.

There are numerous challenges where

every section has to be aware like different position employees should have

proper guidance and knowledge regarding ERP. If proper balancing is not done in

an organization, then it might lead to cultural change which may not be

adaptable to everyone. As ERP is a large software which might take more time

during implementation as it features with the integration system with different

departments. One of the biggest challenges is during ERP implementation which

takes a long time. In a survey, high number of respondents have agreed to say

large time is required during ERP implementation.

While implementing ERP, it needs to

be carefully managed because it may cause massive change. The below listed are

one of the challenging factors which needs to be carefully handled for

successful ERP implementation:

Vital Issues

Change in Structural (Process &

People)

Execution time & cost

Employees Self-esteem

How ERP

is helping the manufacturing industry to manage and support the value creation

of product?

As ERP is helping in different

factors of manufacturing industry which manages and support to create more

quality product. Continuous training is one of the basic requirement of every

organization where technology is emerging day by day so everyone should know

about it in their own field aspect. As an emerging technology the interface and

pattern keep on changing and it makes challenging to the user so most of the

respondents strongly agreed regarding continuous training which directly

implies in standard product. The quality factor is important assets of

manufacturing industries.

With the production, the

organization has to maintain its benchmark with its product. Competitive era

requires to maintain its standardization. So this research wants to assure whether

ERP is helping to maintain standardization of the product. According to survey,

it has been found that high priority is given for product standardization is

better than before whereas some are still confused to find the differences as

it might be due to ERP implementation was done currently. So as result ERP is

very frequently helping in standardization product.

What is

the efficiency of the ERP system in terms of quality?

Efficiency matters with the

monitoring to employees and verifying log reports by top management members.

Ranging from shop level to the root level of an organization ERP helps to

improve business enactment at all. It streamlines automatic operations in terms

of processing to production for gaining larger reflectivity on different aspects

of operations like from entry of order to production line, granary management,

and delivery. It also replies quickly to customer queries whereas helps to

increase accurateness and reliability of secure orders.

Customer demand keeps on changing

whereas this agile feature software adapts to changeability. It controls and

manages rush orders & make exceptions also, handles minimum time left

changes to manufacturing processes with variety of options for planning,

tracing, and action messages which are collaborative.

How is

the service provided by ERP?

Implementation cost varies with the

demand of the software product and brand also with services. Reliability is the

quality of being able to be trusted or believed because of working or behaving.

For long term benefits, during implementation of ERP both training and

education factors play vital role. Well-skilled user’s area unit economical,

extremely impelled and sometimes invent new techniques to avoid wasting time

and improvise business manners. Continuous training approach makes the service

quality better directly proportional to the betterment of product quality.

Future Recommendation

In general, the ERP system confirms

several advantages for business growth. Although the estimated value is not

exceeded after the risk is taken. Together, there seems to be an optimal level

of useful integration in ERP with margins that decrease to a certain level,

consistent with the diseconomies of scope for terribly massive implementations,

as expected. Although our data does not currently allow for a more detailed

analysis of the exact adoption model (due to the lack of detailed data on the

extent of distribution at the worker level) or the long-term impact on

productivity (due to the lack of long-term publication implementation of data

at this time), both topics are promising areas for future research. It may be a

more productive survey if the researcher himself observes from the beginning of

the implementation of an ERP to the production level with control and measurement

of the product, discovering at the same time the effectiveness between the

interdepartmental correlation.

Acknowledgement

The authors acknowledge Lord Buddha

Education Foundation (Asia Pacific University of Technology & Innovation)

for providing us the opportunity to work in this research.

Funding

Nil

Conflict of Interest

Nil

References

- Arachchi, S. M., Chong, S. C., & Madhushani, A. G. (2015). Quality Assurance and Quality Control in ERP Systems Implementation. American Scientific Research Journal for Engineering, Technology, and Sciences (ASRJETS), 70-83.

- Beheshti, H. M., & Beheshti, C. M. (2010). Improving productivity and firm performance with enterprise resource planning. Enterprise Information Systems, 445472.

- Bernroider, E. W. (2008). IT governance for enterprise resource planning supported by the Delone-McLean model of information systems successs. Information & Management, 45, 257-269.

- Blanchard, D. (2012). Supply Chain Management Best Practices. Wiley Best Practices.

- ERP Desk. (2015). 5 Disaster Recovery Strategies for Handling ERP Failure. Retrieved from TOOLBOX: https://it.toolbox.com/blogs/erpdesk/5-disaster-recoverystrategies-for-handling-erp-failure-121115

- Esteves, J., & Pastor, J. (2001, August). ENTERPRISE RESOURCE PLANNING SYSTEMS. Communications of AIS, p. 8.

- Gupta, M., & Kohli, A. (2006). Enterprise resource planning systems and its implications for operations function. International journal of production economics, 687-696.

- Hauptman, O., & Hirji, K. (1996). The influence of process concurrency on product outcomes in product development. IEEE Transactions on Engineering Management, 153-164.

- Institute for Work & Health. (2019, July 24). Cross-sectional vs. longitudinal studies | Institute for Work & Health. Retrieved from Institute for Work & Health: https://www.iwh.on.ca/what-researchers-mean-by/cross-sectional-vs-longitudinalstudies

- Joshi, V. (2017, March 24). The history of ERP systems- from the beginning to now. Retrieved from VersAccounts: http://www.versaccounts.com/blog/the-history-of-erpsystems/

- Karim, A. J. (2011). The significance of management information systems for enhancing strategic and tactical planning. JISTEM-Journal of Insformation Systems and Technology Management.

- NAM. (2011). The skills gap in U.S. manufacturing. Deloitte: NAM.

- Pagell, M., Newman, W. R., Hanna, M. D., & Krause, D. R. (2000). Uncertainty, flexibility, and buffers. Production and Inventory Management Journal, 35-43.

- Rothlin, M. (2016, April 20). An Exploratory Study of Data Quality Management Practices in the ERP Software Systems Context. Retrieved from BORIS: https://boris.unibe.ch/id/eprint/79149

- Rouse, M. (n.d.). What is longitudinal study? Retrieved July 22, 2019, from WhatIs.com: https://whatis.techtarget.com/definition/longitudinal-study

- Sakakibara, S., Flynn, B. B., Schroeder, R., & Morris, M. (1997). The impact of justin-time manufacturing and it infrastructure on manufacturing performance. Management Science, 1246-1257.

- Saunders, M., Lewis, P., & Thornhill, A. (2007). Research Methods for Business Students. Harlow: Financial Times Prentice Hall.

- Shehab, E., Sharp, M., Supramaniam, L., & Spedding, T. A. (2004). Enterprise Resource Planning: An integrative review. Business Process Management Journal, 359-386.

- Su, Y. F., & Yang, C. (2010). Why are enterprise resource planning systems indispensable to supply chain management? European Journal of Operational Research, 81-94.

- Technology Evaluation Centers. (n.d.). SAP ERP vs Microsoft Dynamics 365 ERP Comparison Report. Retrieved July 26, 2019, from Technology Evaluation Centers: https://www3.technologyevaluation.com/store/top/sap-erp-vs-microsoft-dynamics365-erp-comparison-report.html

- Thompson, J. D. (1967). Organizaitons in Action. New York: McGraw-Hill.

- VARGAS-HERNÁNDEZ, J. G., LEÓN, A. d., & VALDÉZ, A. (2011). RESEARCH METHODOLOGY STRATEGIES IN STRATEGIC MANAGEMENT. African Journal of Social Sciences, 46-72.

- Work Wise Software. (2013, November 21). How Much Does ERP Software Cost? Retrieved from WorkWISESoftware: https://www.workwisellc.com/blog/erpsoftware-cost/

This work is licensed under a Creative Commons Attribution 4.0 International License.